Dry Ice Deburring by Nitrofreeze

Burrs are a frequently occurring reality of most machine operators. Drilling, grinding, milling, engraving, or turning operations can all yield unacceptable burrs. To bring a part within tolerance, machined parts must undergo a post-op cleaning to remove unwanted residual burrs.

Burrs are a frequently occurring reality of most machine operators. Drilling, grinding, milling, engraving, or turning operations can all yield unacceptable burrs. To bring a part within tolerance, machined parts must undergo a post-op cleaning to remove unwanted residual burrs.

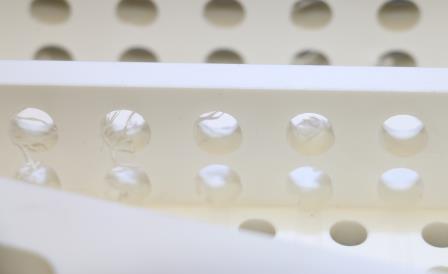

Dry Ice Deburring uses a manually operated, precision dry ice cleaning system to remove hard to reach burrs on a part. Accelerated micro-particles of shaved dry ice serve to freeze and blast away residual burrs. This process is ideal for parts with complex geometries and/or parts that require a media-less clean. Because dry ice sublimates to gaseous CO2 upon impact with the surface, Dry Ice Deburring is effectively a media-free process. Larger parts may also be good candidates for this process.

The Process

Dry Ice Deburring removes minor burrs from parts utilizing accelerated dry ice. See the process below:

What materials can we deburr?

Dry Ice Deburring has proven successful in removing minor burrs from most plastics and rubbers, with a demonstrated preference to thermoplastic polymers. Nitrofreeze has successfully deburred the following materials and more with this process:

Silicones, Nylons, PEEKs, Polycarbonates, Polyurethanes, ABS, Acetals, Delrin, PPE (Polyphenylene Ether), Turcite, Ryton (PPS), EPDM, and many more.

Will cryogenic temperatures or tumbling alter or damage my parts?

See the process in action

More FAQ

Will this process change the surface finish of my parts?

What is the min and max lot size?

Will cryogenic temperatures damage my parts?

I want to try Cryogenic Deflashing prior to running lots of my parts. Is there a way I can sample the process?

I would like to sample the process on my parts

For more information on our PreProduction Engineering Evaluation (PPEE) sampling program contact us at [email protected] or 1-508-459-7447. You may also request to have a Nitrofreeze representative contact you.